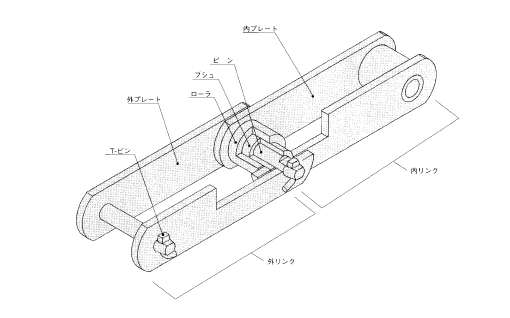

DK Conveyor Chains are available within a wide variety of dimensions, roller sorts, and material and heat treatment. Furthermore, the chains can be utilized for any broad range of application with our in depth collection of attachments and additional features.

Classified by Dimensions

DK Conveyor Chains may be classified into standard, strong H-type and strong Z-type with reference for the size on the base chain.

The Common Conveyor Chain will be the basic type of DK Conveyor Chains, and many attachments, materials, heat remedies, and so on. are available.

The Strong H-type Conveyor Chain was initially formulated as being a chain for bucket elevators with enhanced power and it is now obtainable in the series. A small-sized Robust H-type Conveyor Chain is nearly equal in strength to a large-sized Normal Conveyor Chain, but since the dimensions and form differ, sprockets usually are not interchangeable. Typically, Sturdy H-type Conveyor Chains are greater in power than Typical Conveyor Chains with in regards to the similar roller diameter.

Powerful Z-type Conveyor Chains are additional enhanced in power than Sturdy H-type Conveyor Chains by elevating the height of your inner plates, as well as the sprockets are interchangeable should the nominal amount is definitely the identical. Sturdy H-type Conveyor Chains are utilized in machines in which the plates slide over the floor, this kind of as steady flow conveyors, since the inner and outer plates possess the exact same height.

On the other hand, Powerful Z-type Conveyor Chains exhibit substantial fatigue strength and are used in vertical conveyor bucket elevators.

Classified by Roller Sort

The rollers of a conveyor chain function not simply to engage the sprockets moving the chain but additionally to rotate and travel on the rail, conveying content articles with modest frictional loss. To meet several shapes of rails and avert meandering, and so on., 4 styles of rollers, massive roller, flange roller, medium roller and modest roller.

Moreover, for smoother rotation, we offer massive rollers and flange rollers with built-in bearings (BR and BF rollers, respectively), and UR and UF rollers  with significant clearances in between the bushing as well as the roller to prevent the entry of foreign matters into the bearings. These rollers tend to be utilized in waste processing services.

with significant clearances in between the bushing as well as the roller to prevent the entry of foreign matters into the bearings. These rollers tend to be utilized in waste processing services.

Within this catalogue, huge rollers, flange rollers, medium rollers and smaller rollers are respectively expressed as R-roller, F-roller, M-roller and Roller S.