AN30569 Pulley for John Deere Blend Feed House Areas

▍Usage

A spare components for drive of John Deere combine harvesters.

▍Designation

Making certain the needed stage of rigidity of generate belts of knots and units of agricultural equipment.

Utilized to change worn or broken details in the course of fix work.

▍Properties

Ensuring the required degree of tension of drive belts of knots and units of agricultural machinery.

Parameters AN30569 Pulley

| Bodyweight , W | kg | one.17 |

|---|---|---|

| Inner diameter , d | mm | seventeen |

| Outer diameter , D | mm | 222 |

| Width , Wb | mm | 39 |

| Interior width , b | mm | 33 |

| Shield variety | Bilateral | |

| Defend substance | Metallic | |

| Shaft mounting type | Cylindrical |

The parameters might differ from the actual ones.

Use of AN30569 Pulley

Merge harvester John Deere:925 930 932 935 940 942 945 950 952 955 960 965 965H 968H 970 975 975HY/4 985 985HY4

Related goods

We Also Supply PTO Shafts & Agricultural Gearboxes

If you also want the PTO shafts, simply click here:https://hzpt.com/agricultural-pto-shaft/

We Also Supply Agricultural Gearboxes

Firm Data

You may want gearboxes, hydraulic cylinders or a trailer hitch to get all your machines managing and prepared when you start operating your fields. We at HZPT will ensure your agricultural wants are met, delivering you with products and elements that are appropriate for your agricultural software. We’re proud to offer more than 6,000 elements in stock, so you can be sure we’ll have broken areas in want of substitute. Whether you need to have hitch pins, blades, tines, PTO shafts, bale spears, disc bearings, roller chains, Caroni garden mower parts or sprayers. Even take care of your self to a brand name new tractor seat for a a lot more comfy and comfortable work working day.

HZPT TRANSMISSION GROP, referred to as HZPT for brief, Hzpt is a subsidiary of at any time power,is a Chinese car and agricultural machinery areas company, we do not generate agricultural machinery, we create replacement elements for agricultural machinery. We have been proven for more than twenty many years and have a prosperity of encounter and knowledge. With steady improvement, at any time-energy group has grow to be a globally regarded leader in the automotive and agricultural equipment areas sector. Currently, our merchandise are exported all more than the world, including Asia Pacific, South The united states and Europe.

Advantages of Ball Screws and How They Can Benefit Your Apps

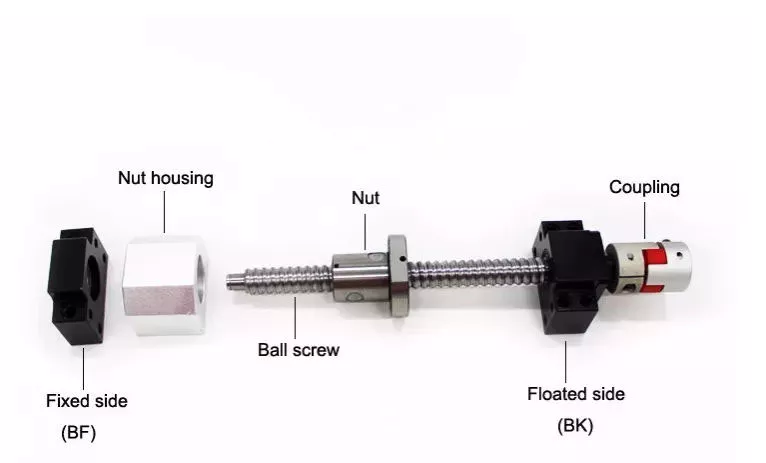

When choosing a ball screw for your application, there are many aspects to take into account. This post will examine large mechanical efficiency, lower friction, multiple fix alternatives, and software demands. Picking the correct ball screw can assist you get the task completed rapidly and efficiently. To make your selection simpler, take into account the subsequent guidelines. Study on to learn about some of the positive aspects of ball screws and how they can reward your apps. Listed here are some of the most frequent kinds:

Large mechanical performance

The mechanical efficiency of ball screws can be calculated employing the axial load examination. The axial load is equal to .5 x FPr / 2Fpr. The elastic deformations are calculated as DL1 and DL2, respectively. Common engineering methods perform at ninety percent trustworthiness however, specific sectors need higher trustworthiness, which has a immediate effect on the dynamic load ability. The axial load check is 1 of the most broadly utilized approaches to establish the mechanical performance of ball screws.

In order to achieve high translation, ball screws have to be developed with substantial stiffness and positioning precision. In addition, higher preloads boost the first driving torque and result in much more friction and heat. Other critical design criteria incorporate low driving torque and diminished slip movement. This implies that the large translation capacity of ball screws have to be effectively matched to the total application. The adhering to are some typical design criteria for ball screws. You can select the ideal sort of ball screw for your needs.

The substantial mechanical effectiveness of ball screw is accomplished by staying away from the frequent sag and pitch difficulty. The ball track design and style will help to minimize the centrifugal pressure. The ball screw’s diameter can be adjusted by changing the centre pitch of the nut on two ball tracks. The nut’s axial load is also adjusted by way of the offset centre pitch. This method allows the users to improve the mechanical effectiveness of ball screw by up to 40%.

When calculating the mechanical performance of ball screw, think about the application’s surroundings, pace, and other aspects. If the software demands precision and accuracy, then the ball screw is the proper choice. The engineering office of a ball screw manufacturer will very carefully overview the software variables and arrive up with a design and style that meets the application’s expectations. Furthermore, some makers even offer custom-made ball screws, which can be tailor-made to your demands.

Lower friction

The working efficiency of a reduced-friction ball screw is characterized by its nominal friction. This screw has a structure that transmits forces via rolling metal balls. The torque is calculated by calculating the load and the guide screw’s proportions. This type of screw can be used for a selection of various apps, which includes hydraulic systems. Go through on to understand far more about this type of screw and how it can support you construct a far more trustworthy and resilient car.

The crucial velocity of a ball screw is higher than that of a direct screw, so this sort of screw can accommodate larger masses and speeds. It also has a decrease friction coefficient, which reduces the volume of heat produced. Large-quality ball screws can face up to longer responsibility cycles than regular guide screws. However, in order to assess the two, you need to take into account the duty cycle. Low-friction ball screws are a lot more resilient than direct screws, and the responsibility cycle is only 1 of the factors you must think about when picking them.

The ball bearings are the most distinguished component of a lower-friction ball screw. Their major purpose is to reduce the friction between the nut and the shaft. With out them, the friction would be too high. This feature is feasible thanks to the ball bearing’s groove profile. Two arcs intersect at the contact factors on the shaft and nut. As a result, the ball bearing lowers friction in a way that is primarily non-existent with out the bearing.

The mechanical performance of a low-friction ball screw is extremely higher. The typical ball screw is up to ninety% efficient, but some types can attain a higher performance. They are typically utilized in device slides, presses, and linear actuators. The large performance of a minimal-friction ball screw tends to make it a great option for several various applications. This kind of screw is manufactured of several principal parts. The ball bearings supply the helical raceway for the ball assembly and threaded shaft is the screw part. The ball screw is comparatively a lot more cumbersome than a traditional leadscrew, but the total dimension is smaller sized than its lead counterpart.

A number of restore possibilities

A broken ball screw will typically display seen physical indications, such as sound or vibration. In addition, worn ball screws will need more horsepower and torque to work. They might also trigger lead accuracy problems. The good news is, there are a number of mend options for ball screws. You can get new ball screws to restore preload and decrease backlash. But there are some warning symptoms to appear out for initial. Maintaining a close eye on your ball screw’s well being can aid you keep away from a costly substitution.

Seem for a ball screw fix business with a established keep track of file of servicing all kinds of ball screws. The support must supply a free of charge analysis and 3 types of services: reload, recondition, and substitution. Reload is the most basic selection and includes cleansing and sprucing the screw and ball nut. Reconditioning or substitution, on the other hand, needs new parts. Pick the 1 that delivers the greatest value for your money.

EP offers an unexpected emergency services and outstanding support for your ball screws. Their Uk services contains supply and global shipping. All ballscrew repairs are covered by a entire services guarantee, and the firm is identified for supplying aggressive pricing. If you do want a ball screw restore, look no even more. Contact K+S right now to go over your particular needs. You may be happy you did. You will help save up to 70% more than buying a new ball screw.

Even though ball screw mend is an effortless and economical selection, it may be essential to have it changed a lot more frequently than the usual. In addition to changing worn ball screws, you could want to contemplate a different variety of fix. This process involves grinding the ball nut and journal diameters again to their unique dimension. Thankfully, degree 4 is the most costly but can restore a screw’s lifespan. This is also the most comprehensive type of restore offered for a ball screw.

Software requirements

A ball screw is an efficient answer for precision movement handle in several apps, which includes automotive and aerospace. These screw-sort gadgets are hugely resistant to corrosion, and the alternating metal-ceramic architecture guarantees intense reliability and sturdiness. For the aerospace sector, a ball screw replaces the standard hydraulic technique, and the solution is used in wind turbine blade pitch and directional placement, solar panel movement, and gate handle in hydroelectric stations. Ball screws are also used in motorised inspection tables, action photolithography equipment, microscopic integrated circuits, and many other apps.

The most essential demands for a ball screw assembly are backlash and bearing help. Backlash is the sum of axial motion between the screw and nut, which leads to positioning glitches. Despite the fact that this axial motion is minimal, it can be as tiny as 70um. If the preload is way too massive, a ball screw may possibly suffer from too much warmth. Relying on the software, the volume of preload necessary can be altered to improve the total overall performance of the gadget.

The choice of screw is decided by the load capacity. For case in point, plastic nuts are generally utilized for mild hundreds, even though bronze nuts are utilized for hundreds that weigh many thousand pounds. Direct screws are not notably reliable in situations the place load requirements are incredibly higher, and a ball screw will often be a greater selection. The lower friction of a ball screw enables it to endure increased duty cycles than a direct screw. When the load needs exceed direct screws’ ability, a ball screw is the better option.

A phase photolithography equipment is yet another instance of an software where ball screws play an critical part. This unit assists companies make microscopic integrated circuits by harnessing the reaction of mild. A stepper is a vital piece of this machine, as it controls the positioning of light publicity on the silicon wafer. High precision is necessary for this application. In the long run, a ball screw will make the process less difficult. Its established document for meeting instrumentation demands is an superb case in point of its worth in the laboratory.

Price

The world-wide market for ball screws is expanding at a steady tempo, but what drives the growth? In the ball screw sector, functionality, price, and analytical predictability are the main worries of OEMs. This market place review supplies in-depth investigation of these market place dynamics. You’ll discover how to ideal contend in the global marketplace for ball screws. Below are some suggestions to help you get began:

Ensure you have a very good grasp of the differences among guide and ball screws. The value of lead screws is dependent on their effectiveness, and some of them can attain C5 level accuracy. Nonetheless, ball screws are more resilient and far more repeatable. In addition to, guide screws can’t obtain large precision since of their sliding motion, which gradually grinds away the precision. As a end result, the expense of a ball screw is far more than compensated by the enhanced performance of OEMs.

To get the ideal price tag for ball screw, look for a company with a sturdy complex drive. Most of these producers have sophisticated tools and stringent quality handle methods. They draw inspiration from the requirements of the industry and have repeatedly improved their technological articles to stay in advance of the competitors. If you are in Pune, appear for a producer with this technological innovation. It will not be challenging to do company with such a provider. The firm will also supply you with speak to information, such as their place of work handle and mobile phone numbers.

When choosing between lead and ball screws, you require to comprehend how they operate and why they are much more trustworthy. Ball screws are much more resilient than direct screws, which is one of the major factors for their reputation. Guide screws, on the other hand, are often used for vertical purposes. Guide screws have a tendency to be less expensive than ball screws, but they have more restrictions. When used properly, however, they can increase the existence and performance of devices. In general, they are corrosion-resistant and provide wonderful style adaptability.